I pressed the "new" rotor with new bearings and end bells into the "new" stator and it is finally acceptable. the only problem is that the bearings are a teeny bit loose on the shaft.

I'll use some LocTite to fix that until I am inspired to get different bearings (not any time soon).

A few hours and some hammered black paint on the "new" end bells and it will be time to build a table a tune up a RAS.

All in good time...

Monday, March 29, 2010

Wednesday, March 24, 2010

Got the new saw and rotor

I tried the new rotor in my restored bells and motor and got very little difference in terms of oscillations.

That being the case I am going to try the new bells and rotor on the restored motor and see if that finally works. If it does I will know the restored bells are shot and just move on from there.

That being the case I am going to try the new bells and rotor on the restored motor and see if that finally works. If it does I will know the restored bells are shot and just move on from there.

Monday, March 22, 2010

Got my rotor back today

Pressed it into the 196 and fired her up, still bad oscillations.

I have come to the conclusion that I must have jacked the rotor while pressing it into or out of a bearing at some point.

New rotor will be picked up tomorrow and we'll see if that helps.

I have come to the conclusion that I must have jacked the rotor while pressing it into or out of a bearing at some point.

New rotor will be picked up tomorrow and we'll see if that helps.

Wednesday, March 17, 2010

I found another GWI

So this No Op Shop is gonna be out of the game.

I found another GWI for parts.

I'll get my rotor back, try new bearings, and if I can't get it smooth I'll pull what I need off of this saw to put my hot rod to work.

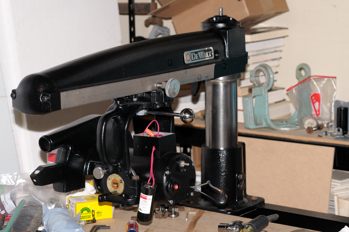

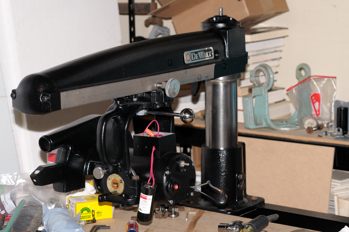

Here's an older photo of it waiting for its rotor:

Since then I've added new hardware in the locations you see rusted hardware. With the motor back together and some shim washers she should be formidable. When this thing is locked it doesn't move at all.

I plan to build a Mr Sawdust "sub" table and bolt it to the bottom of the table between the table and the legs to provide stability and resist deflection.

Click on the images to see larger versions.

I found another GWI for parts.

I'll get my rotor back, try new bearings, and if I can't get it smooth I'll pull what I need off of this saw to put my hot rod to work.

Here's an older photo of it waiting for its rotor:

Since then I've added new hardware in the locations you see rusted hardware. With the motor back together and some shim washers she should be formidable. When this thing is locked it doesn't move at all.

I plan to build a Mr Sawdust "sub" table and bolt it to the bottom of the table between the table and the legs to provide stability and resist deflection.

Click on the images to see larger versions.

Thursday, March 11, 2010

Gotta hate these small shops

So the guy calls me today and says he hasn't started yet, lol.

He wants me to create some drawings of what I want done. Far Out. OK.

When I do so I will post them here for fun in case someone else needs them.

He wants me to create some drawings of what I want done. Far Out. OK.

When I do so I will post them here for fun in case someone else needs them.

Thursday, March 4, 2010

Nope, looks like March 15th

Gotta love these small shops...

Man, I hope this GWI can come back from purgatory. I'm ditching my R1350 and need a daily driver with more power than my 925DLX. I will say this, though. When I fired up the DLX and cut up some wood this weekend I was amazed that it showed no heel whatsoever and it was still perpendicular to the now thrashed table. Vrrrrrrrrop! Right through the wood, easy as pie with a Freud LU83R008.

Unlike my frequently adjusted R1350 this saw apparently can hold its adjustments for 20 years at a time ;-)

Man, I hope this GWI can come back from purgatory. I'm ditching my R1350 and need a daily driver with more power than my 925DLX. I will say this, though. When I fired up the DLX and cut up some wood this weekend I was amazed that it showed no heel whatsoever and it was still perpendicular to the now thrashed table. Vrrrrrrrrop! Right through the wood, easy as pie with a Freud LU83R008.

Unlike my frequently adjusted R1350 this saw apparently can hold its adjustments for 20 years at a time ;-)

Monday, March 1, 2010

She may come back to life this week

Long story short, the motor for this saw was working perfectly before I disassembled it and sent the saw off to be painted. When it came back and I reassembled the motor it was a mess. Massive vibrations, heated up, just a mess.

I took the rotor, along with a different rotor from an MBF that I thought was suspect, to a machine shop that does prototypes for its bread and butter. He put the rotors on an indexing table and, using a dial indicator, he said it "looks a bit off". He mounted it on a lathe and confirmed that the MBF rotor was not straight by .002" on one end and .001" in the other direction on the other end. Interesting...

I engaged his services to hard chrome the bearing mating surfaces on both rotors and have them reground to straight.

In the intervening weeks it occurred to me that it may well have been that I simply pressed the bearings on crooked or that my pressing technique may have actually bent the rotor. In any event, I didn't think it would hurt to start over with a straight rotor.

I'll post a detailed account of my re-assembly this time with pictures and if it is still a mess perhaps someone can tell me what I am doing wrong.

I have 5 saws right now and room for 2 so I can't wait to get the GWI working (or not) and then begin the process of shedding saws and getting back to woodworking.

I also finished the prototype for an electric brake for the GWI which I will do a detailed post on as well. Parts are just under $100.00 and she works like a champ!

I took the rotor, along with a different rotor from an MBF that I thought was suspect, to a machine shop that does prototypes for its bread and butter. He put the rotors on an indexing table and, using a dial indicator, he said it "looks a bit off". He mounted it on a lathe and confirmed that the MBF rotor was not straight by .002" on one end and .001" in the other direction on the other end. Interesting...

I engaged his services to hard chrome the bearing mating surfaces on both rotors and have them reground to straight.

In the intervening weeks it occurred to me that it may well have been that I simply pressed the bearings on crooked or that my pressing technique may have actually bent the rotor. In any event, I didn't think it would hurt to start over with a straight rotor.

I'll post a detailed account of my re-assembly this time with pictures and if it is still a mess perhaps someone can tell me what I am doing wrong.

I have 5 saws right now and room for 2 so I can't wait to get the GWI working (or not) and then begin the process of shedding saws and getting back to woodworking.

I also finished the prototype for an electric brake for the GWI which I will do a detailed post on as well. Parts are just under $100.00 and she works like a champ!

Subscribe to:

Posts (Atom)